Recent Innovations in Elevator Technology

When people think about transportation infrastructure, they tend to think

When people think about transportation infrastructure, they tend to think

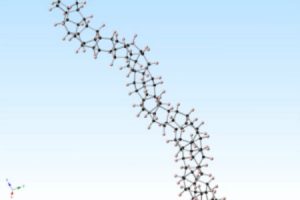

Humans traveling to space have traditionally needed to have supplies

Elevator access control systems grant certain people access to specific

ThyssenKrupp announced a year ago that it was developing the

On October 11, 1887, Alexander Miles patented his revolutionary invention,

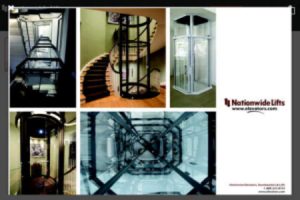

Nationwide Lifts is excited to announce that we recently launched

Copyright 2015-2024 Official Site for Nationwide Lifts | All Rights Reserved | Elevator Compendium | Sitemap